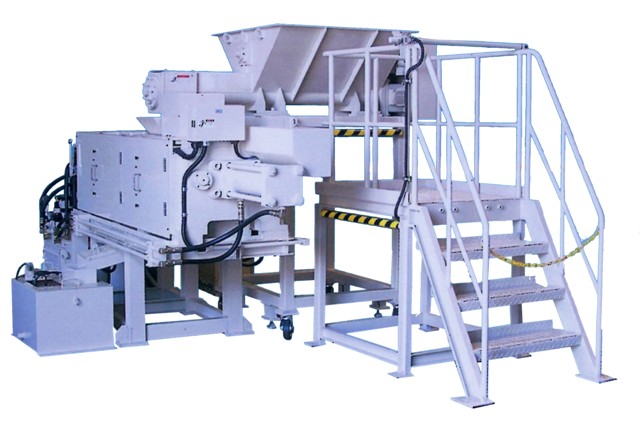

Environmental Machine【MKS・MSZ】

| Production table(kN) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hoeing(MSZ) | 300 | |||||||||

| Suramel Z(MSZ) | 500 | 1000 | 1600 | 2000 | 3000 | 3500 | ||||

| Katamel α(MKS) | 1000 | 1600 | 2000 | 3000 | 3500 | |||||

| Katamel α【aluminum】(MKS) | 1200 | 2000 | 3000 | |||||||

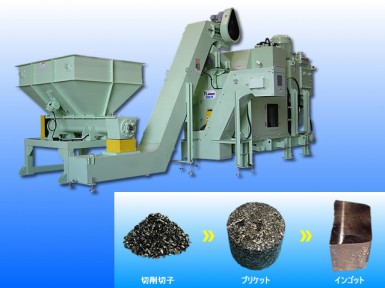

Future of Disposal plant grinding sludge

Casting briquettes were solidified Our machine, it will be the raw material as it is dissolved. Has been achieved, low-cost and non-polluting.

Disposal plant grinding sludge

(Supports Oil soluble & Water soluble in both.)

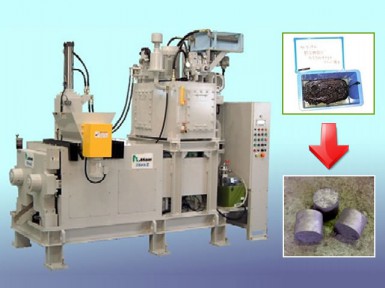

Future of Disposal plant grinding sludge

Abrasive sludge is difficult to briquette. After primary treatment of grinding sludge, paying the cost to go with industrial waste treatment company.

However, the use of our plant, made it possible to briquetting the sludge grinding, and removing the cutting fluid in the process.

And grinding sludge is briquetted, can be reused as raw material for melting.

Suramel MSZ-W 250ton

(Supports Oil soluble)

Suramel MSZ-S 100ton

(Supports Water soluble)

「Guidance of the sample test」

- Briquette test of Chip compacting machine and Disposal plant grinding sludge are possible.

- Briquette processing by our test facility. We will check the Fe content to dissolve the briquette.

For a sample test

- We will receive material from the customer, and then test it. Then we will consider the design of equipment.

If the steel chips

:Please send us your chips into the pails.

If the grinding sludge

:If it is primary treatment, please send into the pails.

If untreated, please send things that, precipitated a few days, accumulated at the bottom, into the pails.

Cost of customer:

- Round-trip transportation costs of materials and Briquette.

- Cost of test, such as X ray analysis. Cost such as travel expenses, if customers come to test.

Our side cost:Test cost of test machine (material (18 liter) pails up to 3 cans)

※If the amount of test material for more than 3 cans will the additional costs. (Separately arrangement)